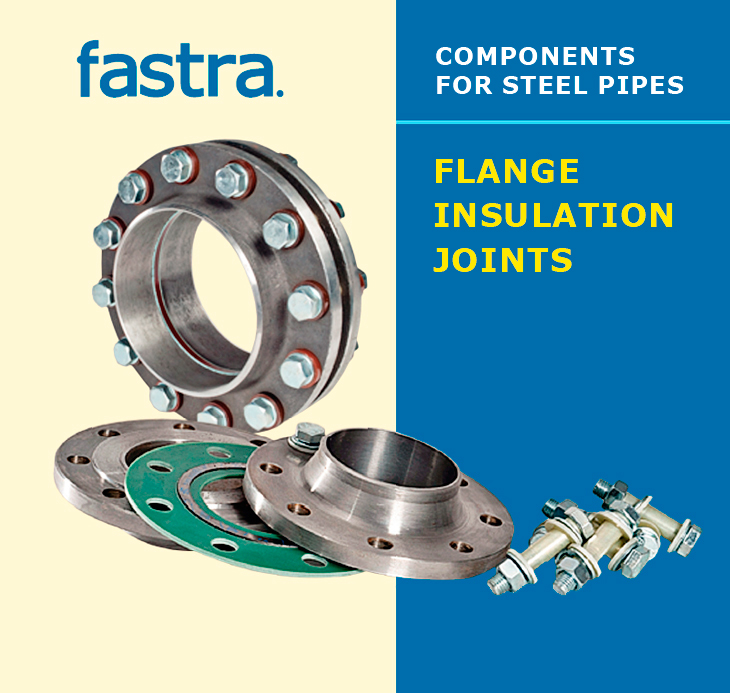

Flange Insulation Joints

Insulation joints are piping parts that are used to break conductivity of steel pipelines in the points where pipes are separated by insulation if the joint needs to detachable.

Diameter of the piping:

DN25 up to DN1200 (or larger)

Media: Gas and liquid – specification is indicated for each type, other media should be consulted

Operating pressure: PN6 up to PN100

Operating temperature: -10°C up to +50°C

Material (steel):

In accordance with DIN or EN standards

Design:

● connecting ends ready to be welded

● as a standard with no internal lining or external anticorrosion protection

● if requested, with pipes welded on both sides, having the length as requested by the customer

● regarding the structure of the sealing there is no need to retighten the screws after they are tighten initially

Advantages of the structure:

● maintenance-free – no tightening of screws

● safety – cellular sealing placed in the groove preventing its blow-off

● reliability – long-term elastic sealing

● Technology – no flange installation

Production and testing:

● as specified by the customer

● in accordance with SCHUCK standards, or in accordance with DIN 3389 (PN4 up to PN16), DIN 1988 (from PN16)

● no pressure test, or pressure test as requested by the customer

● Electric test 2000V

● Insulation and sealing materials conforming to mechanic, electric and thermal requirements of the medium

Czech

Czech