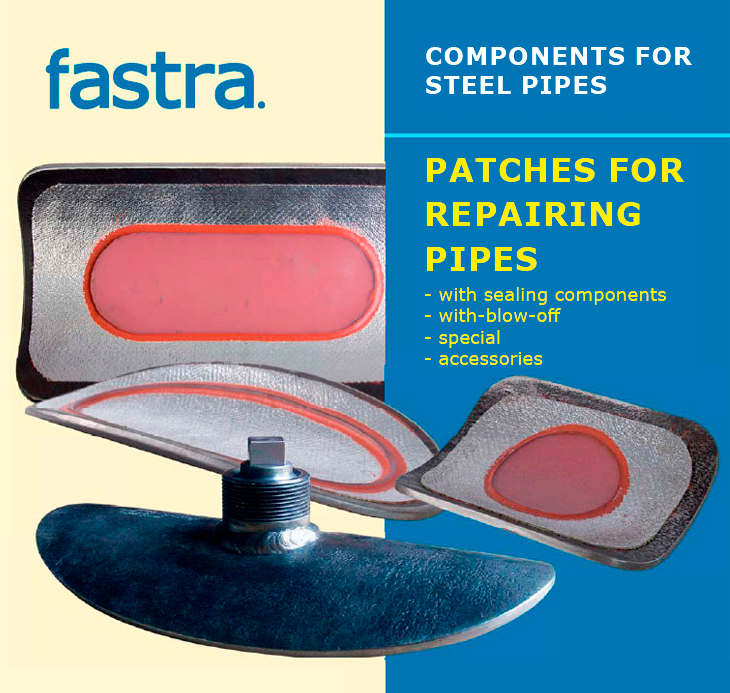

Patches for Repairing Pipes

Repair patches for repairing pipeline of product supply system damaged due to corrosion or mechanical impact.

Repair patches for repairing pipeline of product supply system damaged due to corrosion or mechanical impact. Steel part – a sector of cylindrical part of the piping; its inner diameter follows the outside diameter of the pipe to be repaired. The inner side of the patch is provided with sealing components with high level of thermal resistance When repairing, the patches shall be attached to the damaged part of the pipe and pressed down using a suitable fixture (e.g. UPU device – following the sheet 3.2 hereof). Sealing located on the inner side of the patch will separate gas-tightly the area of the damaged pipeline and the patch edge intended for making the weld joint. After checking for any leakage, the patch shall be welded to the pipe. The version with a relief valve ensures pressure relief of the patch sealing when it is attached and this also ensures safe welding. To handle the stopper and safe diversion of the leaking medium outside the installation area, the installation kit FZ-V (following the sheet 5.2-4.1 hereof) must be used. The upper edge of the neck and the stopper of the relief valve have been adjusted for a safety sealing weld to be made after the repair is completed. Identification details of the patch have been embossed on the outer side of the cylindrical part.

As a standard, supplied for the pipe with dimensions of:

DN 40 up to DN 500

Pressure load:

PN 16 up to PN 40

Czech

Czech