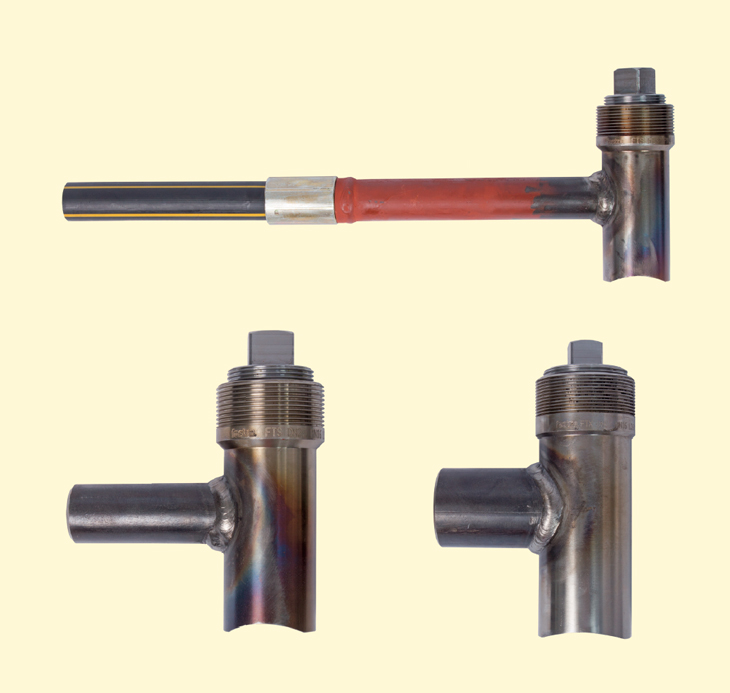

Tee Fitting of FT Type

Tee fitting of FT type are steel fittings designed for realization of branches (connections) through drilling in steel pipeline with internal overpressure with no leakage of medium. After a T-piece is welded on the pipeline and connected with the branch pipe, the pipeline is drilled in and then the T-piece is closed with a stopper with no leakage of media. There is an outside thread in the upper part of the T-piece designed for connection of a drilling set and there is an inside thread for a closing stopper. The lower part of the body is pre-processed for easier adjustment of welding surface before welding. As a standard, T-pieces are supplied with a bevel for V-shaped weld located at the end of a branch outlet, or with an adapter steel/PE for connection of the branch pipes. Standard delivery also includes a closing stopper with an external or internal square end and a sealing O-ring. The stopper and the upper part of the T-piece body have been adjusted for possible circumferential sealing weld. Secondary sealing may also be made through installation of covering lid FV (following 5.1-4 hereof).

Diameter of the branch pipe:

- steel pipe DN/ID 25 up to 100 mm (1“up to 4“)

- PE pipe DN/OD 32 up to 110 mm

Maximum diameter of the drilled hole:

38 up to 89 mm

Outside diameter of pipeline to be welded:

48.3 mm and more

Media:

Natural gas, non-aggressive gas, other media should be consulted

Maximum pressure of medium:

- branch steel pipe – up to 16 bar

- branch PE pipe - up to 4 bar

Material of the fitting:

Steel part: steel properties in accordance with ČSN

EN 1028-1 and ČSN EN 10208-2

Sealing components: EPDM rubber with properties

in accordance with ČSN EN 549

Czech

Czech