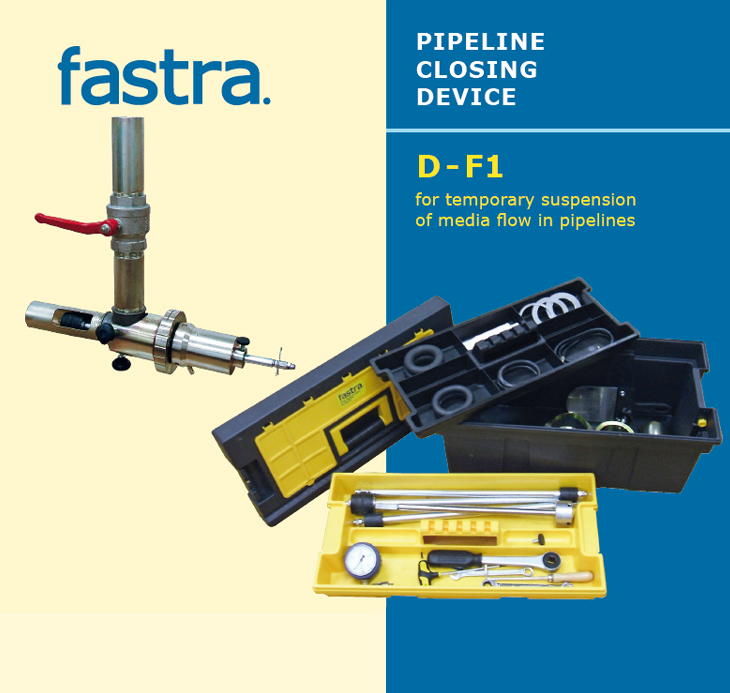

Device D-F1

The D-F1 devices are used for the temporary closing of pipelines with interior gas media positive pressure upstream cleaning T-pieces built in distribution pipelines.

The D-F1 devices are used for the temporary closing of pipelines with interior gas media positive pressure upstream cleaning T-pieces built in distribution pipelines. The stoppler element made of special antistatic rubber located in the loading chamber with a de-aeration valve is loaded to a section of the pipeline upstream the cleaning T-piece after the dismantling of a blade closure using the loading bar. The pipeline is closed by extending the rubber element in the pipeline by turning the control nut located in the control part of the loading bar. The devices are designed so that all works including the closing of the T-piece with a plug could be executed without any media leaks. The devices D-F1 are designed and manufactured as kit systems allowing for a high level of variability. They are compatible with some elements of the devices RUP-F2 or, as the case may be, UDP-F1 (subject to specific conditions). Normally they are supplied as the below described sets or sets individual configured based on customer´s requirements. The devices comply with requirements of CSN EN 1775:2008, art. 8.2.3. as they are designed in a way excluding any leak of media during any operation.

Diameter and material of the closed pipeline:

Steel pipeline DN/ID 32 – 80 mm (5/4“ to 2“)

Media:

Natural gas, other non-aggressive gases, other media subject to consultation with the manufacturer.

Maximum pressure in the closed pipeline:

0,03 bar

Working temperature:

-10/+50°C

Czech

Czech